tooling department

Our Tooling Department and engineers work very closely together overseeing the development of all new parts.

This proximity allows the flexibility to create working prototypes when visualization just isn’t adequate. Our on site tooling design and fabrication capability allows us to design and manufacture all of the necessary tooling and gages needed to create your product to the specifications. In short, we are a one stop shop for your wire and rod manufacturing needs.

finite element analysis (FEA)

A dedicated Finite Element Analysis (FEA) workstation performing computer simulated stress/strain testing of your product or materials.

This FEA analysis assures the part is capable of withstanding its design intent prior to manufacturing. FEA helps reduce cost and compress development timelines by predicting failure areas due to unknown stresses. This capability significantly reduces the cost of manufacturing and testing sample parts.

dedicated project engineer

A dedicated project engineer working with our customer’s production groups.

This single point of communication and coordination of the PPAP process ensures that the products, tools and gauges will be manufactured as designed.

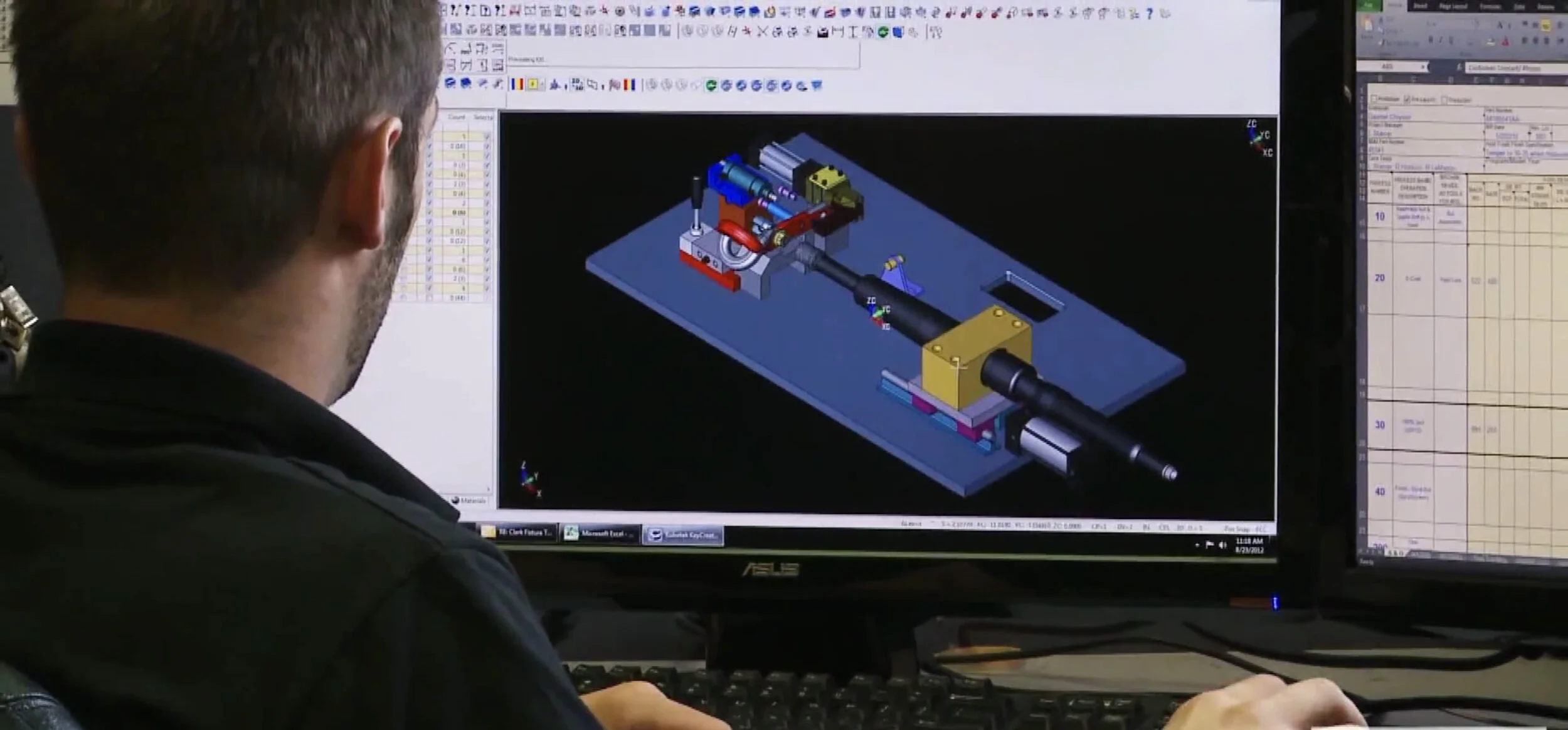

A variety of CAD software and translators:

• Unigraphics NX

• Catia v4

• Catia v5

• KeyCreator

• Solidworks

• Pro Engineer

• Autodesk Inventor

• Autocad

• Parasolid X_T

• ACIS SAT

• IGES

• STL

• STEP

Rapid prototyping

A rapid prototyping machine creates representative parts from durable ABS plastic.

This hands-on visualization assists greatly in the evaluation of new designs or proposals. Typically, we can create a plastic sample the same day we receive a design.